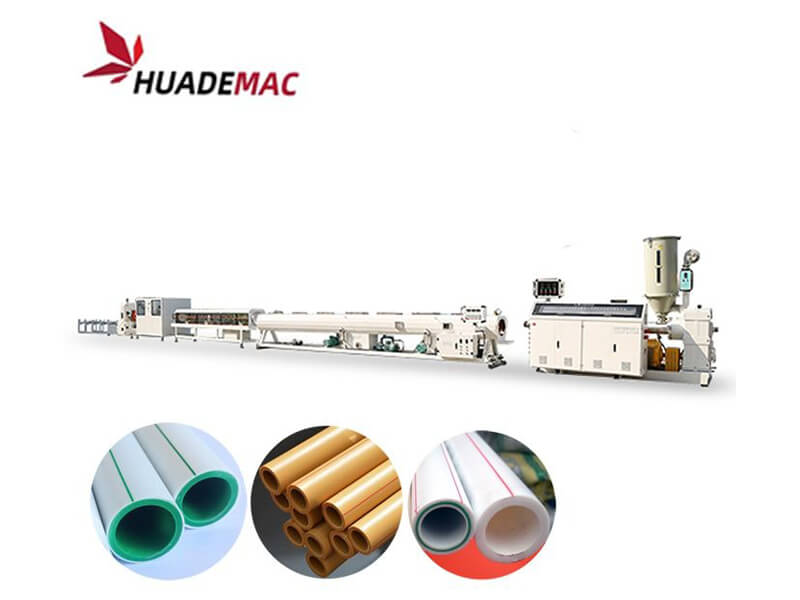

Manufacturer of pipe technology solutions

- Any Questions?[email protected]

- Get in Tough+86-13601562675

There are a lot of PPR production extrusion machinery and equipment on the market, but how many can really operate the machinery proficiently, and only by mastering the performance of the machinery and the characteristics of the raw materials can we produce qualified products.

1. There are scorched marks on the surface of the pipe. The possible reasons are that the temperature of the fuselage or the machine head is too high; the machine head and filter are not cleaned;

2. There are black stripes on the surface of the pipe. The possible reason is that the temperature of the machine head is too high and the filter is not cleaned.

3. If the surface of the pipe is dull, it may be that the temperature of the die is too low or too high.

4. Wrinkles on the surface of the pipe may be due to uneven temperature around the die; too hot cooling water; too slow traction.

5. The roughness of the inner wall of the pipe may be due to the low temperature of the mandrel; the temperature of the fuselage is too low; the temperature of the screw is too high.

6. Cracks on the inner wall of the pipe may be due to impurities in the material; the temperature of the mandrel is too low; the temperature of the fuselage is low; the traction speed is too fast.

7. If the inner wall of the tube is uneven, the temperature of the screw may be too high; the speed of the screw is too fast.

8. There are bubbles on the inner wall of the tube, which may be damp.

9. Pipe wall

The uneven thickness may cause the mouth mold and the core mold to be not aligned; the temperature of the machine head is uneven; the traction is unstable; the compressed air is unstable.

10. The bending of the pipe may cause the pipe wall thickness to be uneven; the temperature around the machine head is not uniform; the cooling groove of the machine head and the traction cutting center are not aligned; the holes at both ends of the cooling groove are not concentric.

11. If the product is brittle, the degree of plasticization of the fuselage may not be enough; the screw speed is too fast; the temperature of the machine head is too low; the viscosity of the resin is too high.

12. If the longitudinal or transverse shrinkage of the pipe is large, the radial difference between the sizing sleeve and the inner diameter of the die may be large (horizontal); the traction speed is high (longitudinal).

13. Sudden slow discharge may cause high temperature in the feeding section of the screw; water entering the fuselage; low melt pressure in the head.