Manufacturer of pipe technology solutions

- Any Questions?[email protected]

- Get in Tough+86-13601562675

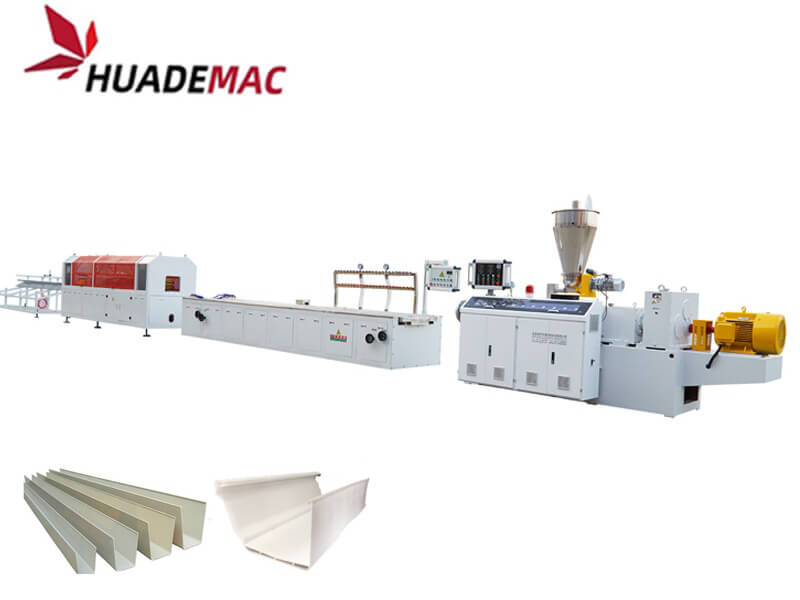

The PVC profile production line includes the main machine, screw mold and corresponding auxiliary machines. It is characterized in that it can produce various specifications and shapes of plastic hard pipes and different products according to the requirements of users. The design of the screw is relatively mature. Good extrusion capacity and plasticizing performance, no burrs, and high pass rate. Third, the vacuum water circulation cooling system is environmentally friendly and energy-saving. Fourth, it is more convenient and faster to replace the die.

PVC profile production line can be divided into pre-coextrusion and post-coextrusion according to the forming conditions and molding state of co-extruded materials. Pre-coextrusion refers to the composite molding of two materials before the extrusion is completed and the product is not yet formed; post-coextrusion refers to the composite molding of one material with another material after it has been fully formed. The advantage of post-coextrusion is that it can make good use of waste materials and is economical.

PVC profile production line can be divided into organic co-extrusion and inorganic co-extrusion according to the different materials of production and extrusion products. Organic co-extrusion includes pre-coextrusion of the same material (such as high-quality raw materials, and adding recovered substances, final co-extrusion) and pre-coextrusion of different materials (such as polymethyl methacrylate and PVC before co-extrusion) and soft The post co-extrusion of rigid PVC and inorganic co-extrusion can be divided into aluminum-plastic composite co-extrusion and steel-plastic composite co-extrusion.

Compared with ordinary pre-coextrusion, co-extrusion plastic profile extrusion line has simple process, flexible application, low scrap rate, easy recycling, bond strength control, and other noteworthy features. Now such technology is mainly widely used in the manufacture of profiled materials for doors and windows with sealing strips.

The traditional pre-co-extrusion profile extrusion line is to extrude molten materials with different rheological behaviors or different colors from two or more extruders to the same molding die. These melts have different flow channels in the molding die. Flow in the center, and then meet and extrude at the die, and vacuumize in the calibrating sleeve to cool and shape.