Constant high output Easy to operate Outstanding,uniform product quality Cost-effective and flexible production

- Any Questions?[email protected]

- Get in Tough+86-13601562675

Constant high output Easy to operate Outstanding,uniform product quality Cost-effective and flexible production

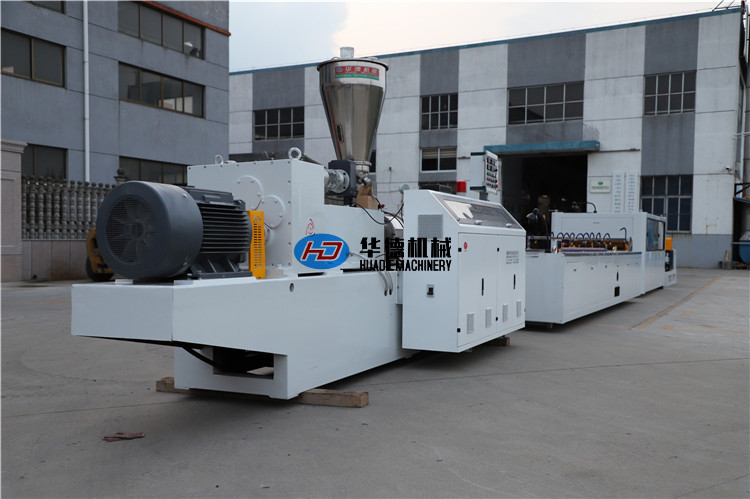

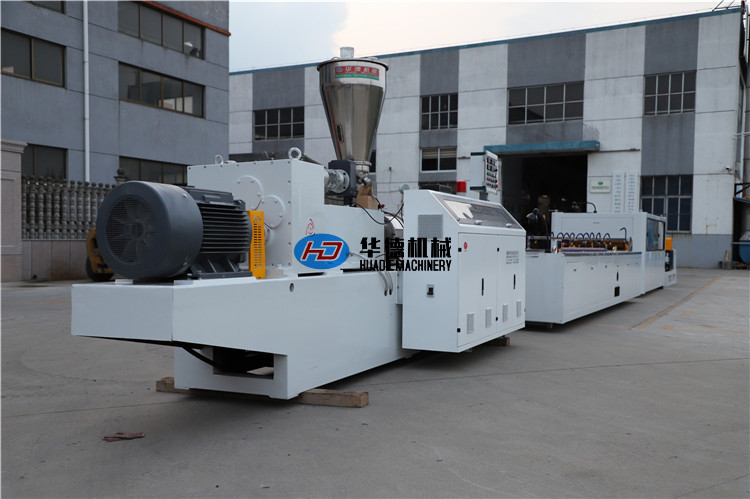

PVC WPC door board machine production line is mainly used for making wpc door board with different width and thickness. The surface of door board can be treated by printing & coated with glossy oil, heat transfer printing or lamination, which can help the door panel get good decorative effect for house door,kitchen,toilet,balcony and so on.

This line applies the conical twin screw extruder with imported inverter,

which provides wide adjusting range and precise temperature control.

High speed extrusion with high capacity and lower power consumption

Barrier design screw with asymmetric slotted barrel design.

PID simple automatic temperature control systems

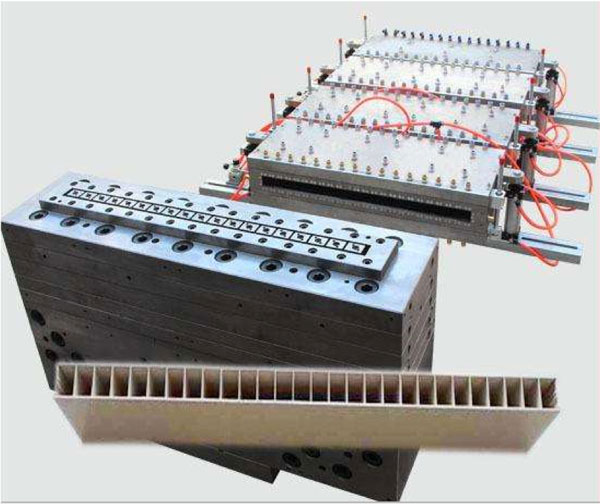

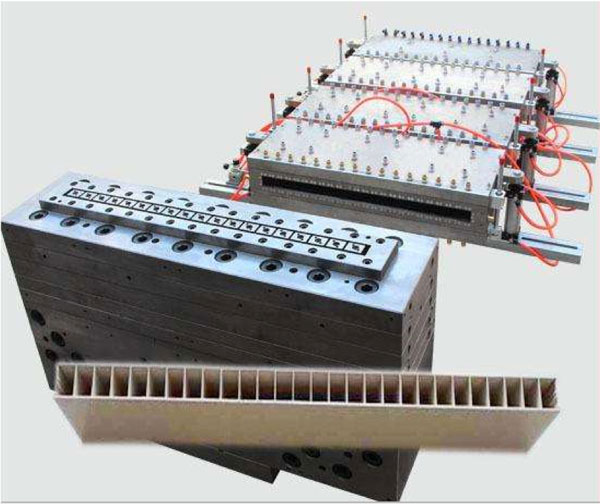

The downstream equipment includes calibration table, hauler, cutter and stacker.

Mix the material→Feed→Extruder→Die head →Haul off→Cut→Stacking

Model | Max.wide (mm) | Extruder model | Max.output(kg/h) | Motor power(kw) |

HD600 | 600 | SJZ80/156 | 280 | 75 |

HD800 | 800 | SJZ80/156 | 280 | 75 |

HD900 | 900 | SJZ92/188 | 500 | 132 |

HD1000 | 1000 | SJZ92/188 | 600 | 132 |