Easy to operate Outstanding,uniform product quality Cost-effective and flexible production Compact and space saving

- Any Questions?[email protected]

- Get in Tough+86-13601562675

Easy to operate Outstanding,uniform product quality Cost-effective and flexible production Compact and space saving

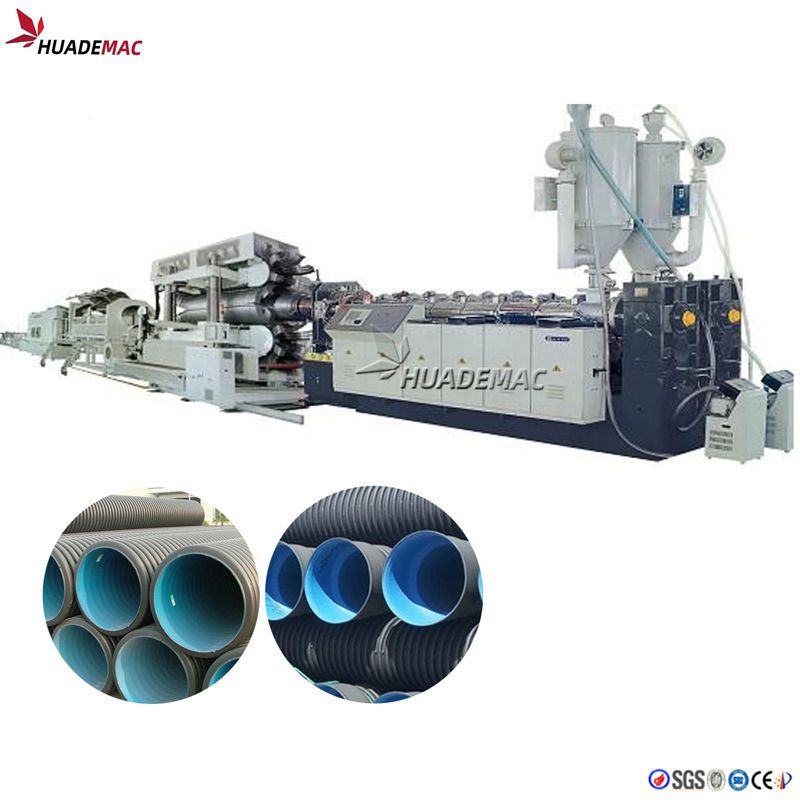

This line is adopting two high efficiency screw extruders to extruding the inner smooth layer and outside corrugated layer.

The forming mould block adopts vacuum forming system, inner template circulate water cooling and auto oil lubrication system.

Good interchangeability of the module; the aluminum forming module uses LY12 high-quality alloy aviation aluminum material with copper content ≥ 5%, precision pressure casting process, high density material, no light pores, long-term use is not easily deformed. Can customize various module waveform schemes according to the user’s requirements.

Supporting automatic DWC cutter, computer control, accurate cutting position, stable running and easy to operate.

Model | Extruder | Diameter (mm) | Extrusion Speed (m/min.) | Capacity (KG) |

SBG-600 | SJ90-33 & SJ75-33 | 225-500 | 0.1-3.5 | 650-800 |

SBG-800 | SJ120-33 & SJ90-33 | 225-800 | 0.1-3.5 | 800-1200 |

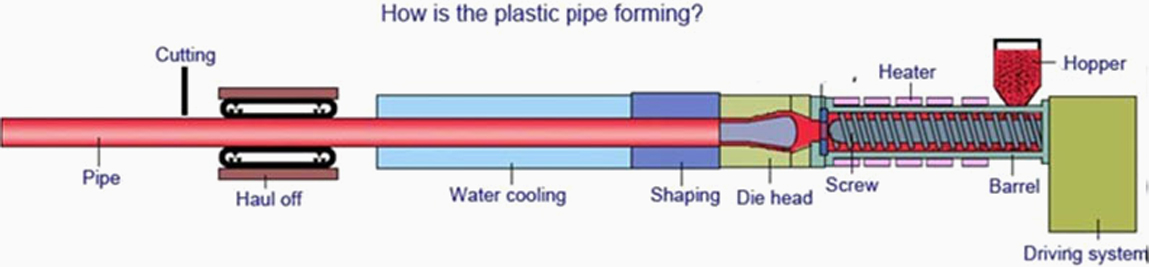

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. With the development of economy, more and more plastics are used in people's daily life. Consequently, a large quantity of plastic extruder, plastic extrusion line, plastic extrusion machine are used to process PP, LLDPE, LDPE, HDPE, PVC, ABS, etc. in pipe extrusion, profile extrusion, filament extrusion, film extrusion, sheet extrusion and pelletizing.

We have focused on plastic machinery over 21 years with rich experience and strong technology .top quality and the turn-key service including installation , test running and training workers in your local factory . we are your trustworthy partner !