Manufacturer of pipe technology solutions

- Any Questions?[email protected]

- Get in Tough+86-13601562675

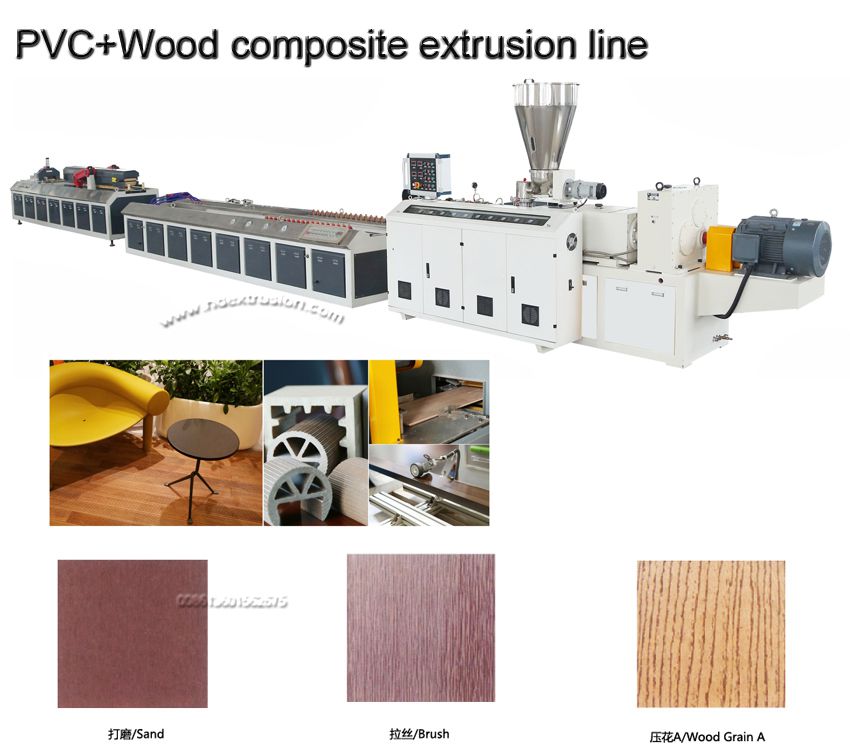

You might not know what exactly is WPC extrusion machine. However, WPC extrusion machine suppliers are here to demonstrate to you what exactly is WPC extruder machine and WPC production line.

The WPC extruder machine and wall panel WPC production line have different specifications when it comes to processing the molds but they can produce voluminous wood-plastic fast wall panels, decorative wood-plastic wall panels, ecological wall panels, economical wall panels and etc. in different sizes, thickness and shapes.

The extruder machines supplied by WPC extrusion machine manufacturers are known for their high productivity rate, efficiency, easy and well-managed operation, equipment stability and high degree of automation.

However, the production line is very strict when it comes to standards measurement of equipment preparation processing. The main components of the WPC extruder machine are in line to the CE and EU demonstration standards. The spare parts of the machine are supplied domestically to ensure that the operation is smooth and efficient.

Here are some systems to differentiate several types of WPC production line:

Vacuum stereotype system has a special cooling system with increased adjustments to further enhance its cooler effectiveness. It has a centralized basic cooling design that’s very quick and easy to use. Moreover, it meets to the production rate and needs of WPC PVC wood plastic wall panels. The cooler of this system is efficient enough to cool down the product more thoroughly and quickly.

Traction is a more stable, powerful and reliable process when it comes to the production of wood-plastic products. It uses a unique traction technology to make the process efficient and smooth. The WPC double-track tractor does not only work smoothly but has a good return on investment rate too.

The design, horizontal cutting comes with a plate traction high-performance speed to keep a good pace. It performs stable operations and the overall design is reasonable and needs minimum maintenance. It produces un-burry and smoother wall panels because it works on high-degree automation. Hence, making the cutting process more accurate.

The cutter dust collector collects all the debris and dust particles from wood-plastic cutting, that's present in the air. It does not only clean the environment but also cleans the stuck residue on the product.

• You can add wood flour, PVC and other additives together to in the WPC extruder machines to make quick wood-plastic wall panels.

• The production rate is quitter higher as compared to the staff-handled method.

The production of sheet extrusion is the main application of this production line. However, if we break down this product furthermore, we are also able to produce the wood-plastic overall house and office doors, wood-plastic wall panels in any shape, size and thickness, PVC hollow insulation or heat-absorbing tiles and much more.

Moreover, it can also produce a wood-plastic wallboard. It is basically an energy-saving composite sheet that has a thin insulated body and high strength. It is also water-resistant, water-resistant and sound-resistant.