Manufacturer of pipe technology solutions

- Any Questions?[email protected]

- Get in Tough+86-13601562675

PE pipes are catching up with and exceeding the consumption of PVC pipes at a higher rate. In production and in current or future projects, it is necessary to understand an important component in the production of PE pipes - the extrusion die.

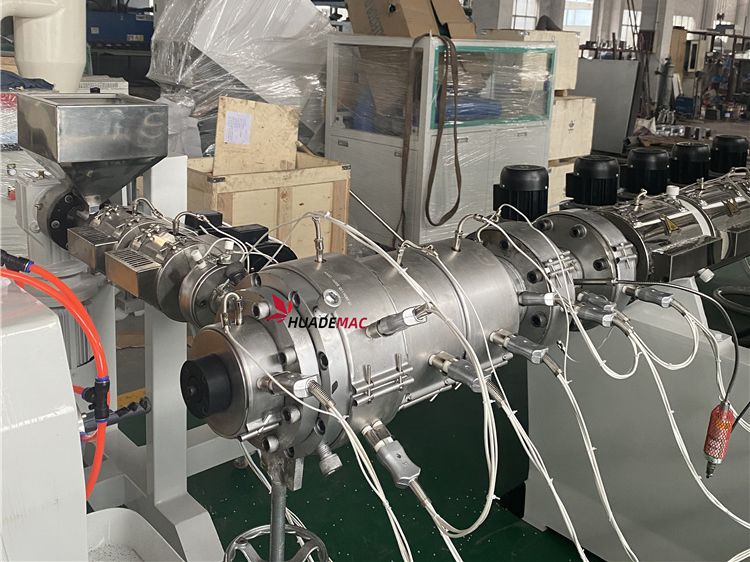

In the current pipe market, PE pipes are catching up with and exceeding the consumption of PVC pipes at a high rate. In production and in current or future projects, it is necessary to understand an important component in the production of PE pipes - the extrusion die. The two commonly used extrusion dies are spiral mandrel die and screen basket die. Now, these two kinds of dies are discussed separately for your reference.

In the pipe extrusion line, no matter PVC pipe or PE pipe, the die head plays a very key role in the product quality. Its function is to make the melt extruded from the extruder pass through the entire die head evenly. The pipe die head is adapted to the requirements of the extruded product, and plays a decisive role in the work efficiency and economy of the entire production line. The two basic requirements for the die head are:

(1). The die head must be adapted to the material to be processed; (2). The die head must be designed in strict accordance with the extrusion volume and the section size of the pipe.The development process of polyolefin die.

For the extrusion of polyolefins, the bracket-type die was developed to the later commonly used screw-type and screen-basket-type dies. The purpose is to eliminate the clamping line caused by the die head as much as possible, so that the materials entering the die head are well mixed and the melt is more homogenized.

The fluid distribution part of the die head is a bracket type, the die head for producing small diameter pipes is a cross bracket type, and the die heads for producing large diameter pipes are mostly six or eight ribs. The biggest disadvantage of this type of die is that if the pressure in the front compression section is too small, the merge line is sometimes not eliminated very well. There must therefore be a high enough pressure to re-merge these separated streams. This requires a relatively high-strength structure, so the overall weight of the die is high. This type of die is generally used for extrusion of PVC pipes.

The easiest way is to put a breaker plate behind the support, and the several streams caused by the support are divided into many smaller streams. Thus, the mechanical stress is pushed forward from the bracket portion, and the parting line is generally relieved by the large amount of small flow. This PE die is mostly used in the production of low density polyethylene and small diameter pipes. In the past, the die head used for the low-density PE drainage and irrigation pipes produced by our company in the West Plant was this type of die head. Now this type of die head has been eliminated, and it is still used in some small private factories.

Bracket dies with breaker plates are rarely used in existing medium and high density polyethylene pipe production. And multi-purpose spiral mandrel die and screen basket die. These two kinds of machine heads have solved the problem of eliminating the parting line better. The core of the spiral mandrel die is a spiral mandrel, and the core part of the screen basket die is a tubular body with a large number of holes, that is, a mesh stack. Now the structure and working principle of these two kinds of commonly used dies are described respectively.